PROFESSIONAL ROOF CONSULTANCY AND SPECIFICATION SERVICES

PROFESSIONAL ROOF CONSULTANCY & SPECIFICATION SERVICES

Welcome to TD Roofing Consultants!

With over 40 years’ experience of working in the roofing industry, we have worked with some of the UK’s leading manufacturers of roofing and waterproofing materials. Our expertise spans a vast array of products and systems, including BUFR (built-up felt roofing), Polymeric Single Ply (e.g. PVC/TPO), Cold Applied Liquids (e.g. PMMA and Polyurethane technologies) and Monolithic Hot Melt.

UNDERSTANDING THE DIFFERENT TYPES OF ROOF SURVEY

At TD Roofing Consultants we understand that surveying a flat roof to determine its condition can often be challenging, especially as it is extremely difficult to detect the extent of any issues purely from a visual assessment. That’s why a thorough and accurate survey carried out by a professional roofing expert makes sense and is a worthwhile investment to protect your building. By spotting damage or problem areas early you can potentially save thousands of pounds, whereas delaying or adopting a less professional approach can potentially lead to unnecessary damage to your property along with costly roof repairs and associated fees.

To ensure that you get the most out of your roof survey it is important to know which kind of survey you need. There are a range of different options available, with each one offering particular criteria and benefits. Below you’ll find a comprehensive guide to the various roof surveys offered by TD Roofing Consultants, enabling you to determine which type will be right for you.

As the name suggests we start with a comprehensive walk of the roof in order to carry out a full visual roof survey. This is essentially a physical examination of your roof by one of our experienced roof surveyors and it will include a photographic summary of our findings. We will also undertake both core sampling and moisture probe analysis of each roof being surveyed so that we can gain the full facts about the existing roof structure and build-up. All tested areas are sealed and made completely watertight after carrying out the test.

This method of roof surveying is a very effective way to establish the moisture content in the existing roof build-up and helps to identify potential problems that may exist.

TDRC’s Electronic Leak Detection Service provides a non-invasive means of detecting pinhole leaks and similar imperfections in a roof’s waterproofing membrane. Any defects are identified to within mm accuracy, enabling targeted and effective repairs to be effectively carried out rather than needing a complete roof replacement. Often referred to as a “wet test”, this method can be used with or without the addition of water (with different testing apparatus) making it an ideal roof leak investigation method for many scenarios.

So how does this technology work? Because all roof membranes are essentially non-conducting, the electric pulse from the wire ring circuit chooses a path across the moisture to where the leak is located. This testing method eliminates the dangers and potential damage that can be caused by traditional flood testing, and even pinhole leaks that aren’t visible to the naked eye can be identified.

Electronic Roof Integrity Testing is a non-destructive test used to verify the waterproofing integrity of a recently installed roofing system.

The wet test method, also known as earth leak detection or “Wet test” relies on the electrically conductive properties of water and the insulating properties of the membrane to be effective. This highly accurate test simply identifies pulsed electric fields of microscopic proportions and homes in on the source with a sensitive meter. Since its introduction, this has become the preferred test for most waterproofing systems as it is highly accurate in detecting breaches and simple to implement, typically replacing the traditional method of flood testing of roofs.

Roof Integrity Testing is used on both new build and refurbishment projects where clients require the peace of mind the roof is watertight before completion of a project. It is also a useful tool in Building Leak Investigations, as one of several methods employed to locate the source of water ingress into a building.

Please Note: Electronic testing is not a catch-all test, even though it is often sold as such. Although this test method is suitable for most types waterproofing, certain membranes are incompatible, such as EPDM. The roof build-up or type of deck may also be a limiting factor. We have developed other techniques for such circumstances. Please call us for further advice.

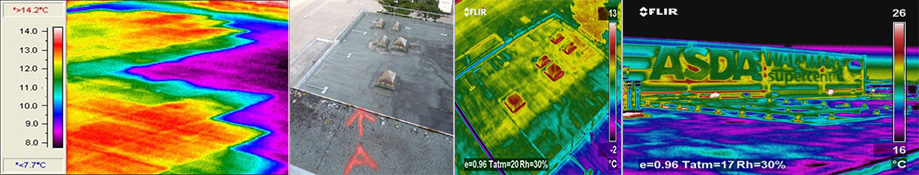

When trying to assess the extent of entrapped moisture, visual inspection is never enough and this is where infrared technology proves invaluable. Thermographic roof surveys utilise infrared technology to accurately identify anomalies within the existing roofing system.

So how does this technology work? The roof absorbs energy from the sun and from the building heating system and then releases this energy as infra-red radiation. In areas where the existing waterproofing has broken down the roof structure will be wet, and as a result it contains more energy – called Hot Spots – which takes longer to cool down. In other words, the physical features of the various elements within a roof system are often changed when they are wet.

The rate at which the roof cools down at night is different on wet parts of the roof, even if the moisture is trapped underneath an apparently dry surface membrane. Infra-red thermography clearly identifies these areas using different colours, making potential problem areas much easier to identify. Another benefit of this type of survey is that it is non-destructive and can be carried out quickly and easily. In addition, by identifying specific areas of water ingress, the client can see which parts of the roof need to be stripped and which can be overlaid. In most cases we can therefore save clients time and money, allowing for more accurate budgeting & programming of roof maintenance.

Perfect for Asset & Remedial Inspections

Asset inspection used to be time-consuming and put people in risky scenarios. Using a drone to capture building data is a safer and easier way of inspecting buildings and roofs, helping to identify potential issues in waterproofing integrity, factory equipment, chimneys and storage tanks.

Professionally piloted drones can quickly spot flaws and issues in any kind of structure or asset – e.g. missing tiles, corrosion, vegetation etc. This then enables problem areas to be efficiently targeted by specialist repair contractors, optimising any time involved and minimising associated costs.*

WHY CHOOSE TDRC?

When you work with TDRC you will benefit from our significant industry experience and expertise, which will help ensure that your projects run smoothly and successfully.

AN INDEPENDENT, IMPARTIAL SPECIFICATION SERVICE

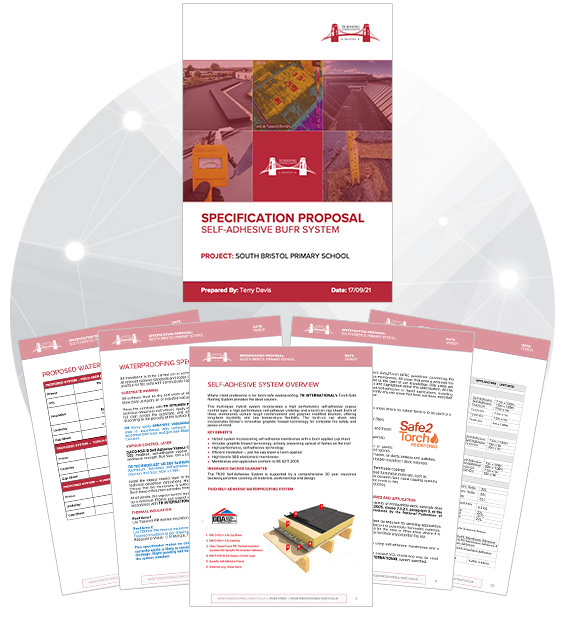

Once we have all the facts on board in relation to the condition of your roof, we will produce a bespoke, fully tailored specification proposal. We have no particular ties to any manufacturer and do not receive any commission for the specifications we produce. You can therefore be assured of an independent and impartial service that truly delivers the solution that’s right for your building.

Our comprehensive specification documents typically include the following:

GET IN TOUCH WITH TD ROOFING CONSULTANTS TODAY

Follow TDRC On Social Media